MDO – Multidisciplinary Design Optimization for Launchers and Entry Vehicles

Project ObjectivesThe objective of the MDO framework is to provide an industrial grade tool which provides all functionality for the multidisciplinary vehicle design optimization of launch and reentry vehicles. The type of launcher shall be flexible with respect to number of stages, strap ons and chosen material and propellant. The used discipline models shall be selected such that All-At-Once optimization shall be possible and that the final design is robust against the inaccuracy of the discipline models. This required a clear improvement first of all for mass estimation models, second for propulsion system models and third for aerodynamic models in case launchers. In addition it is important to provide analysis functions to evaluate the quality of the design considering, e.g. the controllability, and a link of the MDO workflow to other workflows like GNC design or detailed structural and propulsion system design. Therefore the user shall be able to specify the following design requirements:

The output of the MDO framework presents

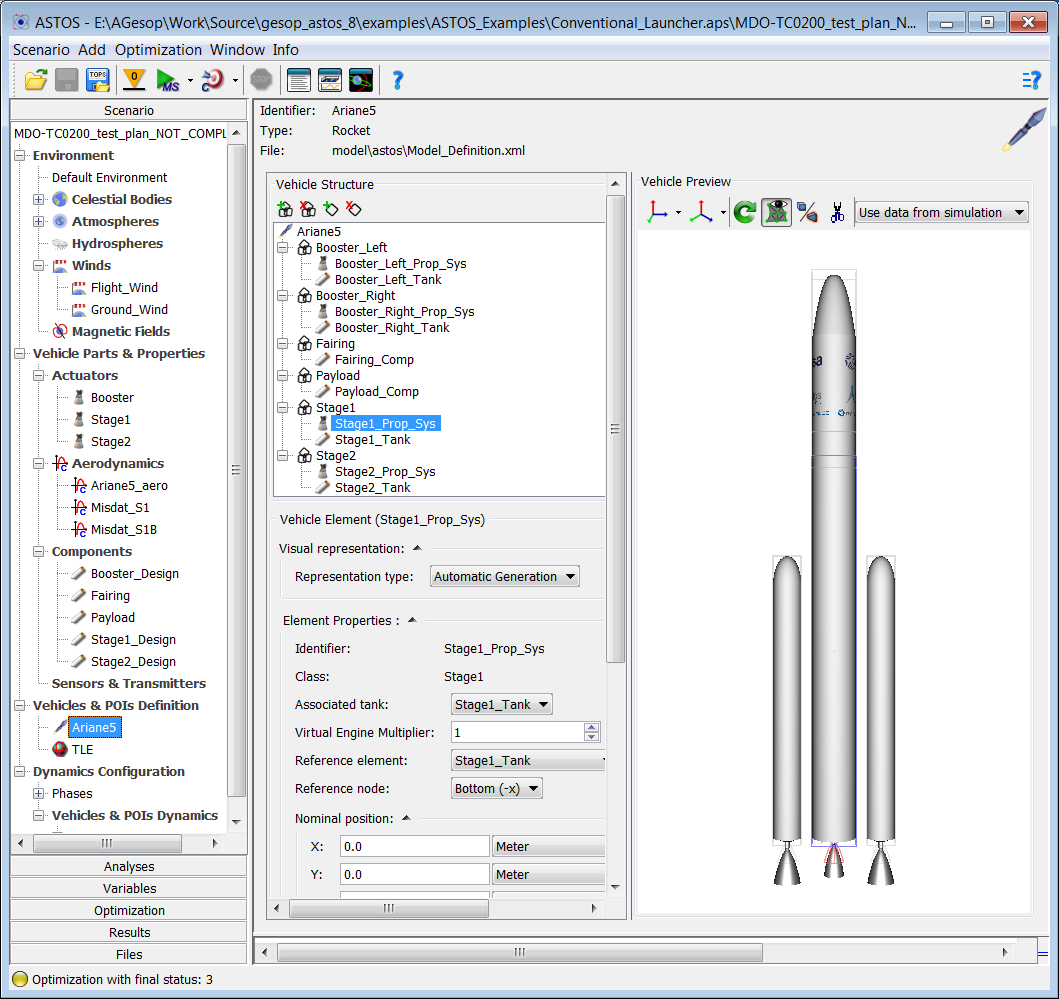

ArchitectureThe MDO framework builds up on the existing ASTOS software, which has been extended for basic MDO functionality in the frame of ESA contract 22047/08/NL/ST. Within this MDO project ASTOS will be further improved in various disciplines and analysis methods. Especially ASTOS will be linked with the structural optimization software ODIN and the rocket propulsion analysis software RPA. While ASTOS is responsible for the whole scenario definition, the optimization itself and the analysis, ODIN is used first of all to compute mass regression tables to be used during the ASTOS optimization, second for the validation of ASTOS' structural design analysing the safety margins and third for the export of a FE-model. FeaturesASTOS is a general purpose astronautics software for mission and system analysis and trajectory and vehicle design analysis. The sophisticated graphical user interface provides rapid configuration and post-analysis capabilities. The figure below shows a screen shot of ASTOS, which presents in the left tree view an overview of the different input sections of ASTOS. The main window presents the selected Vehicle Builder of the launch vehicle, which allows assembling the launcher components and equipment such as thrusters.

ASTOS provides:

Detailed documentation and tutorials are provided with ASTOS, which is commercialized as COTS software. ODIN (Optimal Design INvestigations) is an answer to the need for a quick structural sizing tool within the MDO process. It is designed to perform a pre-dimensioning of main structural components basing on well-known numerical methods, thus providing a first assessment with respect to stage/launcher mass budget and consequently to launcher performance. The pre-dimensioning performed by ODIN relies on the usage of a random search method in order to assess a mass optimised design fulfilling user defined safety criteria. User inputs of ODIN are material, stiffening concept, geometry and dimension load case of shell structures like cylinder, cone, bulkhead, y-ring and strut cone. The objectives of ODIN are

| |||||||||||||||||||||